From Our Hands to Your Home: Inside Our Mattress-Making Process

A closer look at the materials, craftsmanship, and standards behind your best night’s sleep.

At Dreamify, we have three core tenets: quality, transparency, and convenience. Our mattress production process is designed to maintain these values at every step. We want to make sure that our mattresses are well-made, competitively priced, and perform better than the competition. Here’s how each premium Dreamify mattress is made, from our hands to your home.

It Starts With Quality Materials

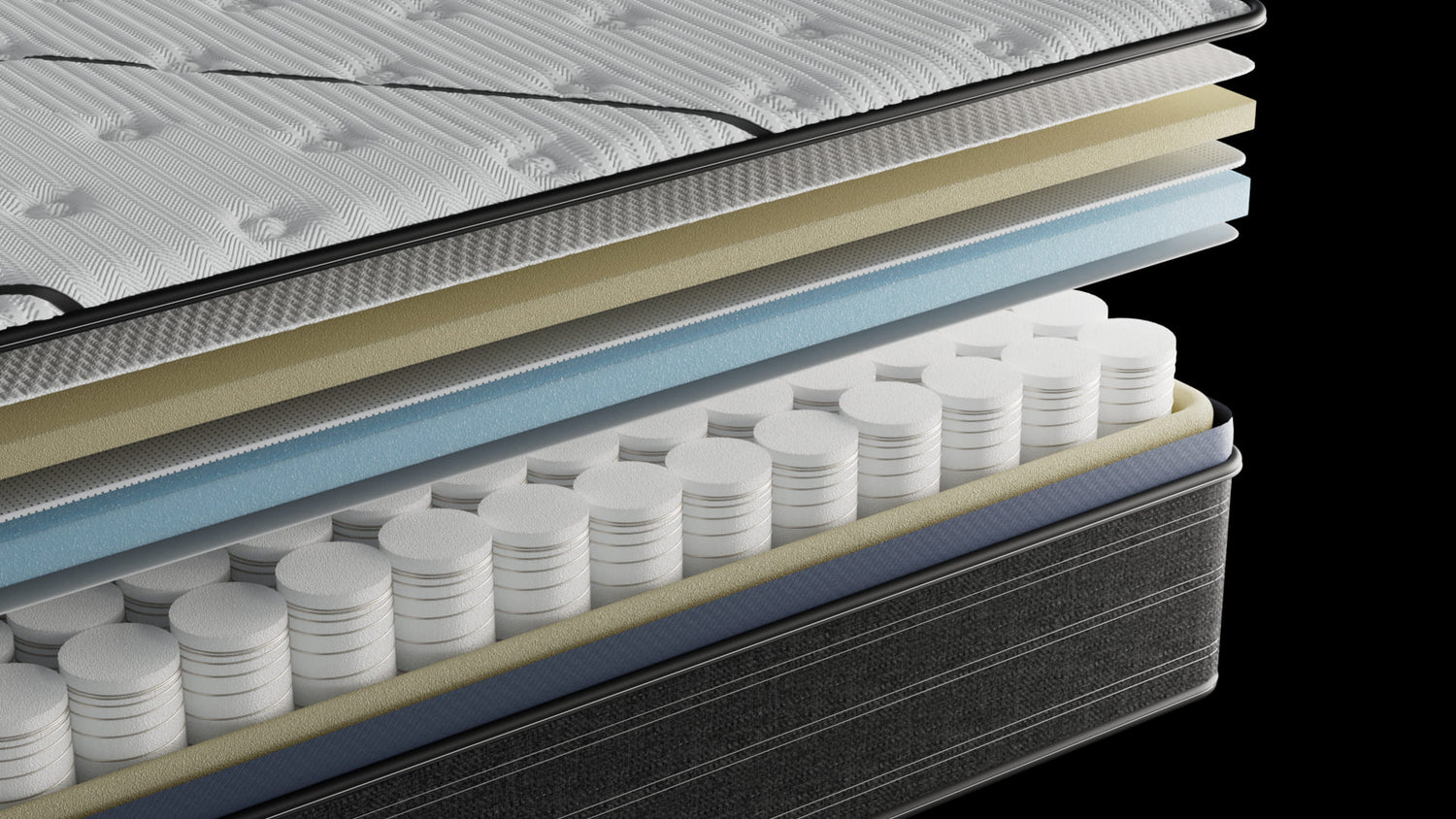

Dreamify mattresses are the product of years of mattress expertise and design knowledge. Our team puts together a list of important performance features that customers want and need. They work through the process of matching materials to their purposes, ensuring proper layering, and keeping their designs simple but effective.

All of the materials used to create Dreamify mattresses are OEKO-TEX certified, hypoallergenic, and completely fire-resistant. From our coil layers to the foam and fabrics that create better comfort, the materials we use are of the highest possible quality.

Expert Cutting, Layering, and Assembly

With our materials chosen, assembly begins. Each layer of foam and coils is expertly crafted, meticulously cut, and carefully layered. These materials are bonded together to create a solid, structurally-sound mattress that holds up to years of use.

Our design team ensures that the materials are layered for the maximum benefit, so we make sure that each mattress is carefully constructed.

Finishing Touches

Dreamify mattresses are hand-finished. The professionals that finish our mattresses take the utmost care to make sure that every detail is perfect. From stitching to embroidery, we oversee every part of the process to ensure that our mattresses meet quality standards even at the surface level.

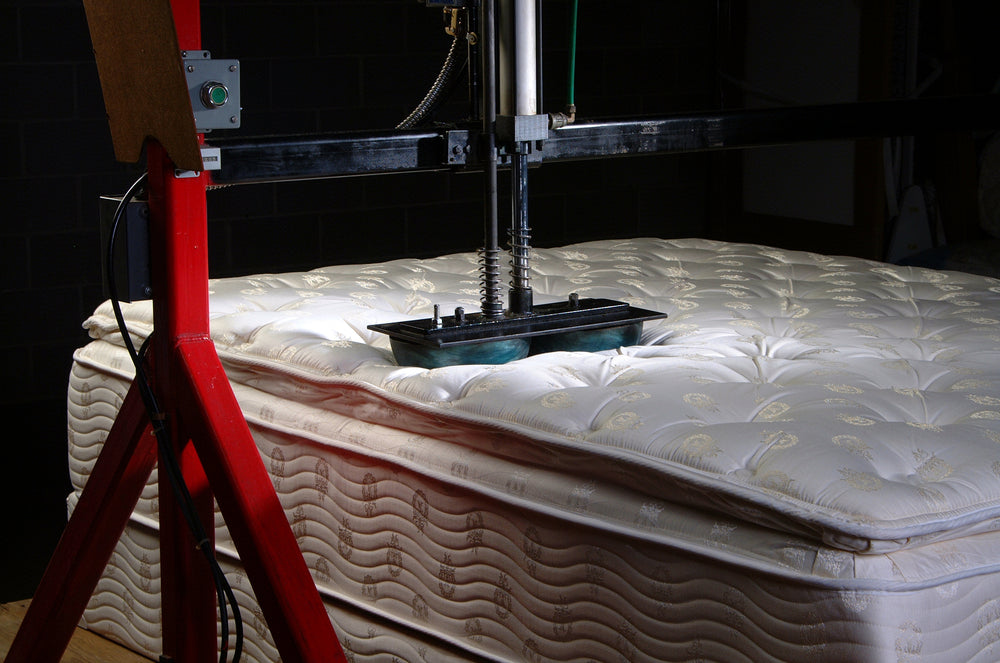

Intensive Quality Control

Once each mattress is complete, our expert team checks for defects. We follow an exhaustive quality control process to ensure that each mattress meets our stringent standards. One of our core values is unshakable quality, so we don’t rush this process. Every part of the mattress is checked for issues, loose threads, and any damage that occurs during manufacturing.

Every mattress that leaves our facility must meet quality control standards before it’s sold to you.

Compression and Packaging

After we make sure that our mattresses are ready for your home, we package them for safe, simple delivery. The mattresses are compressed using advanced technology and 20 tons of vacuum pressure. This compression doesn’t harm the mattress in any way, but it simplifies shipment and makes setup more user-friendly.

Each mattress is compressed tightly into an easy-to-move Dreamify box. Now it’s ready to be shipped right to your door!

Why it Matters

It’s important to us that you know how your mattress is made. We want to make sure we maintain transparency and the highest craftsmanship standards for our mattresses. This means letting you in on every step of the process so you don’t feel like you’re left in the dark.

We stand by our experts, production team, and quality control at every level of manufacture. Your high-quality mattress should be comfortable, perform well, and remain durable for years to come. We also have a robust Warranty and Returns policy for your peace of mind.

Shop Dreamify Mattresses

Explore our full collection of high-quality mattresses at competitive prices.

Pressure relief

Sink into deep comfort and let your body fully relax. Our memory foam mattresses deliver targeted pressure relief and excellent motion isolation. They’re perfect for couples or light sleepers. Designed to hug your curves and reduce tossing and turning, so you can wake up pain‑free and well‑rested.

-

Best value

Sold outFirmnessComfortCooling

Sold outFirmnessComfortCooling- Twin (38x75in)

- Full (53x75in)

- Queen (60x80in)

- King (76x80in)

- California King (72x84in)

$699.00 Choose optionsSold out -

Most popular

Sold out

Sold out12-Inch Memory Foam

4.65FirmnessComfortCooling- Twin (38x75in)

- Full (53x75in)

- Queen (60x80in)

- King (76x80in)

- California King (72x84in)

$799.00 Choose optionsSold out -

Premium choice

Sold outFirmnessComfortCooling

Sold outFirmnessComfortCooling- Twin (38x75in)

- Full (53x75in)

- Queen (60x80in)

- King (76x80in)

- California King (72x84in)

$1,099.00 Choose optionsSold out

Balanced support

Get the perfect balance of comfort and support with our hybrid mattresses. The combination of responsive coils and plush foam ensures proper spinal alignment, breathability, and long‑lasting durability. This option is ideal for hot sleepers and anyone who prefers a slightly bouncier feel.

-

Best value

Sold out

Sold out10-Inch Hybrid

4.61FirmnessComfortCooling- Twin (38x75in)

- Full (53x75in)

- Queen (60x80in)

- King (76x80in)

- California King (72x84in)

$699.00 Choose optionsSold out -

Most popular

Sold out

Sold out12-Inch Hybrid

4.67FirmnessComfortCooling- Twin (38x75in)

- Full (53x75in)

- Queen (60x80in)

- King (76x80in)

- California King (72x84in)

$969.00 Choose optionsSold out -

Premium choice

Sold out

Sold out13-Inch Hybrid

4.61FirmnessComfortCooling- Twin (38x75in)

- Full (53x75in)

- Queen (60x80in)

- King (76x80in)

- California King (72x84in)

$1,199.00 Choose optionsSold out -

Premium choice

Sold outFirmnessComfortCooling

Sold outFirmnessComfortCooling- Twin (38x75in)

- Full (53x75in)

- Queen (60x80in)

- King (76x80in)

- California King (72x84in)

$1,379.00 Choose optionsSold out

Subscribe to our emails

Be the first to know about new collections and exclusive offers.

- Choosing a selection results in a full page refresh.

- Opens in a new window.